RFD60 Digital Ultrasonic Flaw Detector

★ User friendly dialog interactive helps operations like Calibration, making curves, etc.

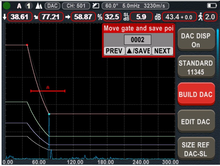

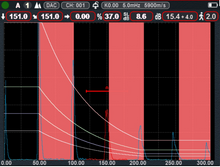

★ All tools you need: DAC, AVG, AWS, Weld diagram,etc.

★ Pulse Repeatition Frequency: 10-3000Hz precise adjust, high speed scan, no miss out.

★ High Signal to noise ratio, clear and stable echo, anti-noise design, perfect for tough working conditions.

★ 10-digit AD, high speed sampling leads to better echo diagram with all details. Sensitive and can detect even tiny flaws.

★ Crystal clear true-color display. Helpful user interface makes the operation much easier.

★Unlimited USB data storage.,PDF reports output.

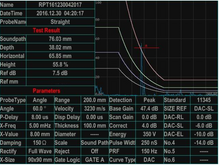

Specifications:

Range:0-10000 mm ,at steel velocity

Material Velocity:1000~10000 m/s

Pulse Repetition Frequency:10-3000Hz

Dynamic range:≥38dB

Linearity: Horizontal: +/-0.2% FSW, Vertical: 0.25% FSH, Amplifier Accuracy +/-1 dB.

Resolving Power:>40dB (5P14)

Sensitivity Leavings:>65dB

Reject (suppression): 0 to 80% full screen height

500 independence setup, any criterion can be input freely, we can work in the scene without test block;

Big memory of 1000 A graph

Test Modes: Pulse echo, dual element and thru-transmission

Probe Types: Single Straight, Single Angle,Daul Straight, Daul Anlge,Thrugh

Gate Monitors: Two independent gates controllable over entire sweep range

Units: Inch or millimeter

Power Requirements: AC Mains 100-240 VAC, 50-60 Hz

Display Delay: -20 to 3400 µs

Probe Delay/Zero Offset : 0 to 99.99µs

Internal rechargeable Li-ion battery pack rated 7.2V at 5600 mAh

10 hours nominal operating time depending on display brightness

4 hours typical recharge time

H×W×D(mm):240×160×45 (mm)

Weight :1.0kg

Operating Temperature: -10℃ to 50℃

Storage Temperature: -30℃ to 50℃

Pulse Energy: 200V, 300V, 400V, 500V selectable

Rectification: Positive half wave, negative half wave, full wave, RF System

Gate Monitors: Two independent gates controllable over entire sweep range

Sensitivity: 120 dB max in selectable resolution 0.1, 1.0, 2.0, 6.0 dB.

Transducer Connections: BNC or LEMO

Functions:

Automated display precise flaw location(Depth d、level p、distance s、amplitude、sz dB、ф).

Flaw sizing: Automatic flaw sizing using AVG/AVG or DAC, speeds reporting of defect acceptance or rejection.

Automated calibration of transducer Zero-point, Angles, Front edge and material Velocity .

Convenient to make and use DAC and AVG to evaluate the echo, the curve can be modified and compensated.

Connectting U-disk,the unit can get unlimited memory,PDF reports out put and Upadte system.

Color Bscan.

Weld diagram.

There are 15 standards of in the unit.

AWS D1.1.

Curved Surface Correction feature.

Crack Height Measure function.

Magnify gate:spreading of the gate range over the entire screen width.

Auto-gain function.

Envelope: Simultaneous display of live A-scan at 60 Hz update rate and envelope of A-scan

display.

Peak Hold: Compare frozen peak waveforms to live A-Scans to easily interpret test results.

Scan Freeze:Display freeze holds waveform and sound path data.

Alarm:Beep and LED.

Real Time Clock.

Fill echo.

Capture mark.

Echo color within the Gate.

What's in the Package:

Portable Ultrasonic Flaw Detector

Straight Beam Transducer (2.5 MHz, Φ20)

Angle Beam Transducer (4 MHz, 8 mm×9 mm, 60°)

Interconnect Cable for the transducer (Q9-C5,or optional C9- C5)

Rechargeable Li-Ion Battery Package, 8 hours

Power supply/charger unit

| Designation | Quantity |

| Main unit | 1 |

| 1.5A/9V power adaptor (110v-240v) | 1 |

| probe connecting cable | 2 |

| probe connecting cable | 1 |

| Carrying case | 1 |

| Instruction manual | 1 |

| Straight transducer | 20mm 2.5MHz(One) |

| Angle transducer | 8x9 60 degrees 4MHz(One) |

| Rechargeable battery | 1 |

List of options (optional items will come free with standard configuration package)

| Designation | Quantity |

| Serial Cable | 1(9 pin) |

| Communication software for PC | 1 set |

By default, the display language is English, we also provide other language packages that user can choose to install such as: Portuguese, German, Italian, Chinese, Korean, etc.